14/16 Grade: The Ultimate Guide to Understanding and Utilizing Its Importance

In the world of manufacturing and construction, the term "14/16 grade" holds significant importance. This guide aims to provide a comprehensive understanding of what the 14/16 grade signifies, its applications, and why it is essential in various industries. From the definition and characteristics to its significance and utilization, this article will delve into all aspects of the 14/16 grade. So, let's dive right in!

Minerals

1. Understanding the 14/16 Grade

The 14/16 grade refers to a specific quality standard used in the manufacturing and construction sectors.

It represents a rating system that assesses the performance and durability of various materials.

The grade is typically based on a scale of 0 to 16, with higher numbers indicating superior quality.

In the context of 14/16 grade, it suggests a material that possesses exceptional strength and reliability.

2. Characteristics of 14/16 Grade Materials

Materials that meet the 14/16 grade standards exhibit several key characteristics. These include:

a) High Strength: 14/16 grade materials are known for their exceptional strength, enabling them to withstand heavy loads and extreme conditions.

b) Durability: With their robust composition, 14/16 grade materials offer excellent durability, ensuring a longer lifespan compared to lower-grade alternatives.

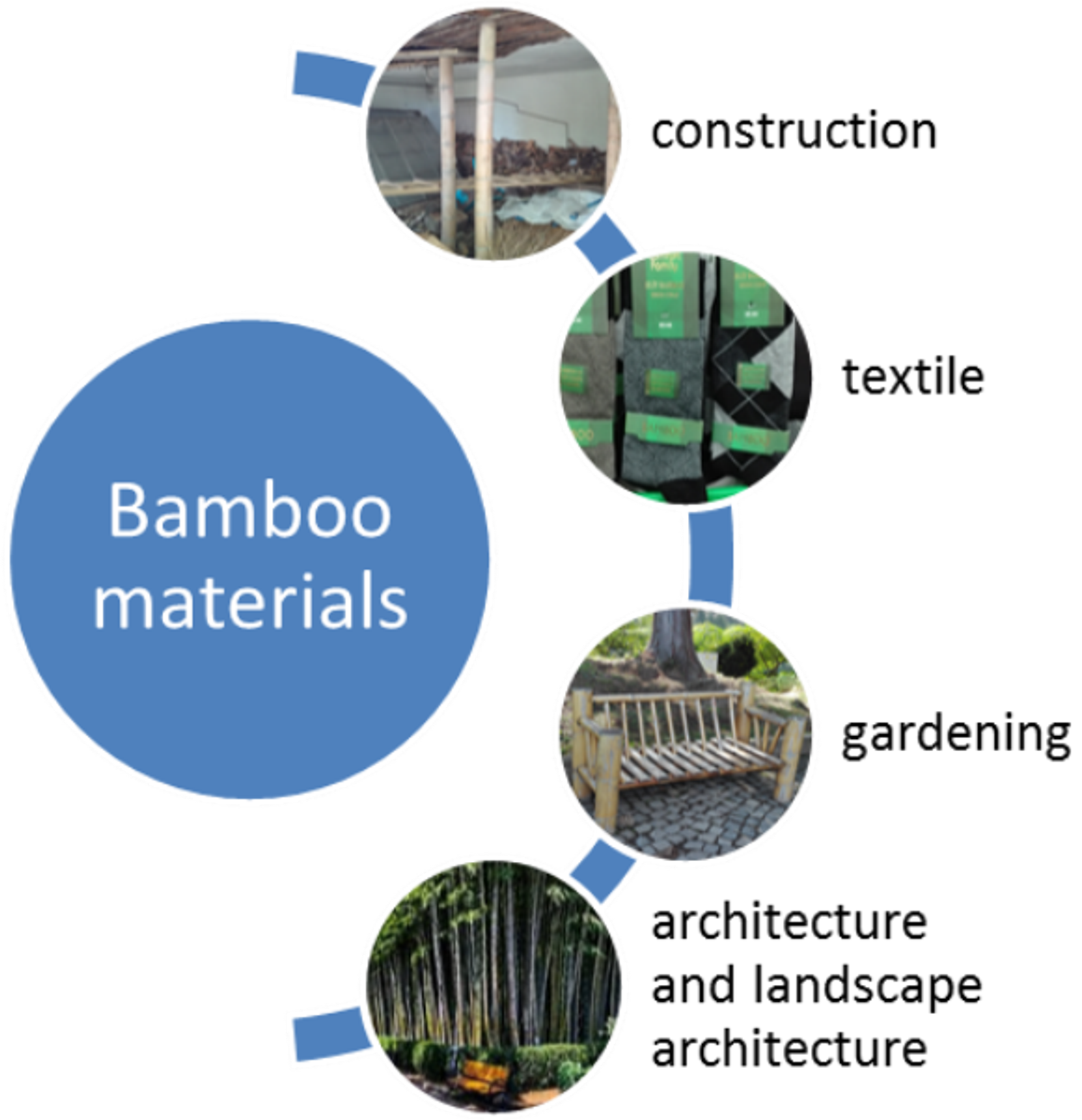

Sustainability

c) Resistance to Corrosion: Another essential attribute of 14/16 grade materials is their resistance to corrosion, making them ideal for applications in corrosive environments.

d) Structural Integrity: 14/16 grade materials provide reliable structural integrity, ensuring safety and stability in various construction and manufacturing projects.

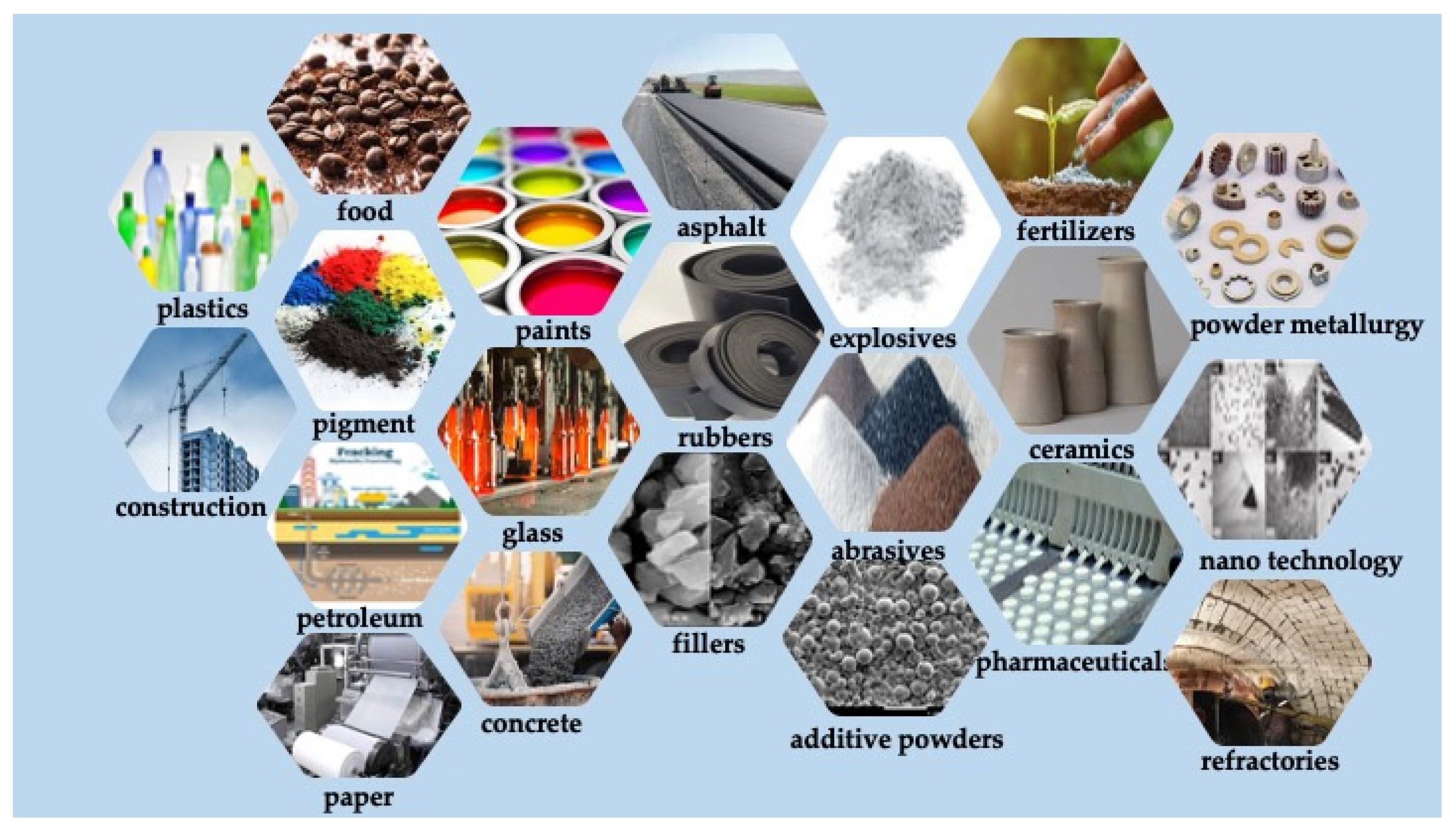

3. Applications of 14/16 Grade

The versatile nature of 14/16 grade materials allows them to be utilized in a wide range of industries and applications. Some prominent uses include:

a) Construction: From high-rise buildings to bridges and infrastructure projects, 14/16 grade materials play a crucial role in ensuring structural stability and safety.

b) Manufacturing: Industries such as automotive, aerospace, and heavy machinery rely on 14/16 grade materials for their strength and durability in manufacturing components and parts.

c) Oil and Gas: Given their corrosion resistance, 14/16 grade materials find extensive application in oil and gas exploration, production, and refining processes.

d) Marine: The marine industry benefits from 14/16 grade materials due to their ability to withstand harsh saltwater environments, making them suitable for shipbuilding and offshore structures.

4. Significance of 14/16 Grade Materials

The significance of 14/16 grade materials stems from their ability to meet stringent quality requirements. The use of such materials ensures:

a) Safety: In critical structures and applications, the high strength and structural integrity of 14/16 grade materials contribute to enhanced safety and reduced risk of failures.

b) Reliability: 14/16 grade materials offer a reliable solution for long-term performance, minimizing maintenance needs and associated costs.

c) Cost-effectiveness: While 14/16 grade materials may have a higher initial cost, their durability and extended lifespan make them a cost-effective choice in the long run.

d) Customer Satisfaction: Utilizing 14/16 grade materials in projects enhances customer satisfaction by providing them with products and structures that exceed their expectations in terms of quality and reliability.

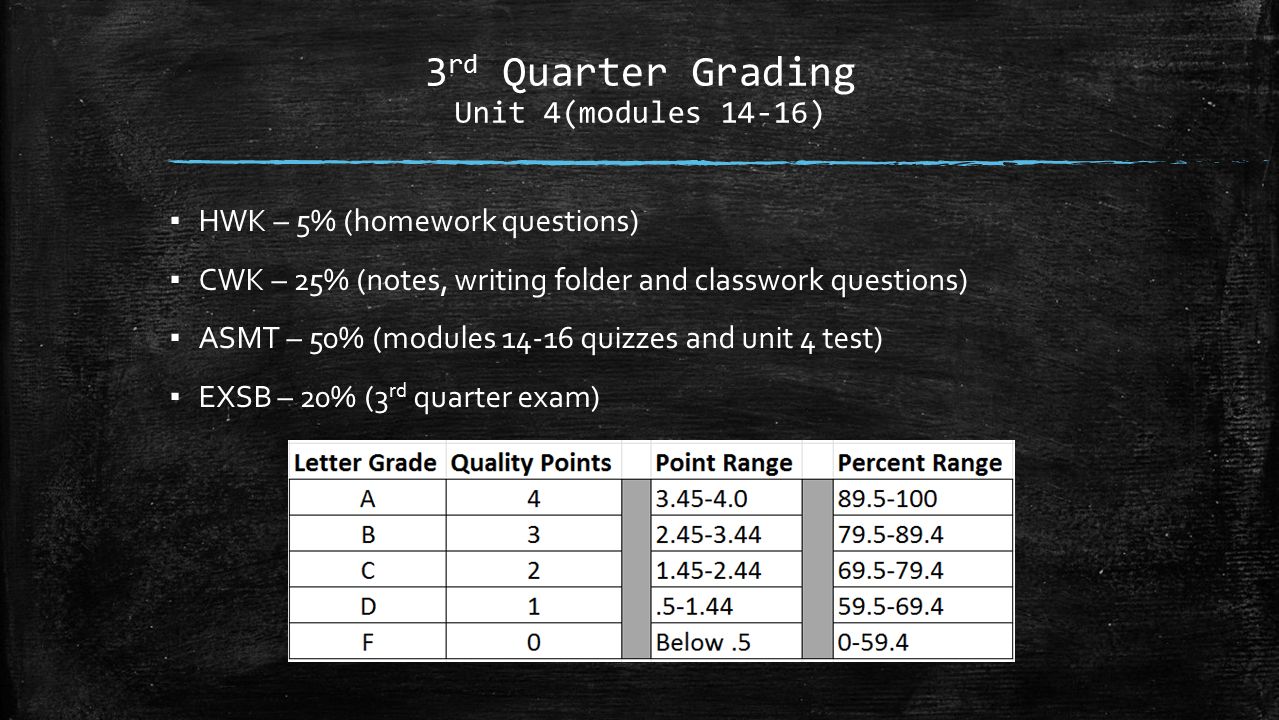

5. Selecting and Testing 14/16 Grade Materials

To ensure the use of authentic 14/16 grade materials, it is crucial to follow a comprehensive selection and testing process. This includes:

a) Supplier Evaluation: Choose reputable suppliers known for delivering materials that adhere to the required quality standards.

b) Material Certification: Verify the authenticity of the materials by obtaining proper certification and documentation from the supplier.

c) Quality Testing: Conduct thorough quality testing to confirm that the materials meet the specified 14/16 grade requirements, including strength, durability, and corrosion resistance.

Quality Testing

In conclusion, the 14/16 grade represents a quality standard that signifies superior strength, durability, and reliability in materials. Understanding the characteristics, applications, and significance of 14/16 grade materials is essential for professionals in the manufacturing and construction industries.

By selecting and utilizing these materials, companies can ensure the safety, reliability, and long-term performance of their products and structures. Stay ahead in the industry by embracing the importance of 14/16 grade materials and incorporating them into your projects.