Exploring Effectiveness: Do Command Strips Work on Metal?

Command Strips are a popular choice for hanging decorations and organizing spaces without causing damage to walls. But how well do these adhesive strips perform on metal surfaces? This guide delves into the effectiveness of Command Strips on metal, offering insights, tips, and best practices for achieving optimal results.

Table of Contents

- Introduction to Command Strips

- How Command Strips Work

- Effectiveness of Command Strips on Metal

- Types of Metal Surfaces and Considerations

- Best Practices for Using Command Strips on Metal

- Creative Uses for Command Strips on Metal

- Common Challenges and Troubleshooting

- Conclusion: Maximizing Command Strip Performance on Metal

Introduction to Command Strips

Command Strips are a line of adhesive products designed by 3M for damage-free hanging. They come in various forms, including hooks, picture hanging strips, and cord organizers, making them versatile tools for home and office use. Known for their easy application and removal, Command Strips have become a go-to solution for those looking to avoid drilling holes or using nails.

How Command Strips Work

Command Strips use a proprietary adhesive technology that allows them to adhere strongly to surfaces while also being removable without leaving residue. The strips consist of two parts: one that sticks to the wall and another that sticks to the object being hung. By pulling the tab at the bottom, the adhesive stretches and releases, making it easy to remove without damage.

Effectiveness of Command Strips on Metal

Key Points:

- Strong Adhesion: Command Strips generally adhere well to smooth, non-porous metal surfaces due to their strong adhesive properties.

- Surface Cleanliness: For best results, the metal surface should be clean, dry, and free from dust, oil, and debris.

- Weight Limits: Adherence and holding power can vary depending on the weight of the item and the type of Command Strip used.

do command strips work on metal

Types of Metal Surfaces and Considerations

When using Command Strips on metal, it's essential to consider the type of metal surface:

- Painted Metal: Command Strips adhere well to painted metal, provided the paint is in good condition and the surface is clean.

- Bare Metal: Bare metal surfaces, such as stainless steel or aluminum, may require additional cleaning to ensure proper adhesion.

- Textured Metal: Command Strips may struggle to adhere to textured or uneven metal surfaces due to reduced contact area.

Best Practices for Using Command Strips on Metal

1. Surface Preparation:

-

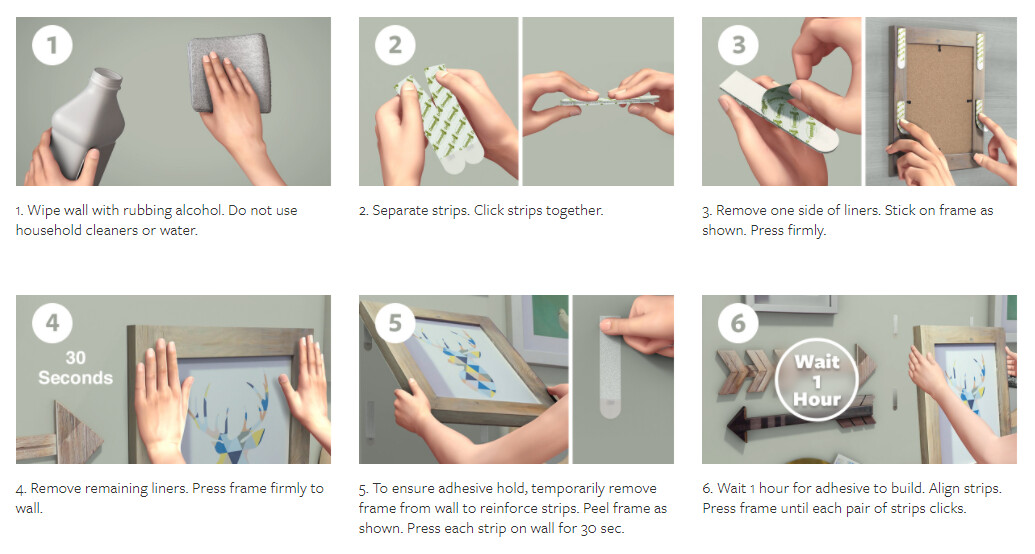

Clean the Surface: Wipe the metal surface with rubbing alcohol or a mild detergent to remove any oils, dust, or residues.

-

Dry Thoroughly: Ensure the surface is completely dry before applying the Command Strip.

2. Application:

-

Temperature Considerations: Apply Command Strips at room temperature. Extreme cold or heat can affect the adhesive bond.

-

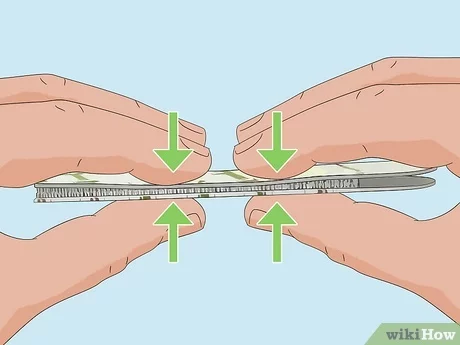

Press Firmly: Press the strip firmly against the metal surface and hold for at least 30 seconds to ensure a strong bond.

-

Wait Before Use: Allow the adhesive to set for at least one hour before hanging items to ensure maximum holding strength.

3. Weight Limits:

-

Check Packaging: Refer to the Command Strip packaging for specific weight limits. Using the appropriate strip for the weight of your item is crucial.

- Distribute Weight Evenly: For heavier items, use multiple strips to distribute the weight evenly and reduce the risk of failure.

do command strips work on metal

Creative Uses for Command Strips on Metal

- Office Organization: Use Command Hooks to hang office supplies and tools on metal filing cabinets or metal desks.

- Kitchen Storage: Attach Command Strips to metal kitchen appliances to hang utensils, towels, or lightweight pots and pans.

- Garage Solutions: Organize tools and equipment by attaching Command Strips to metal shelves or toolboxes.

Common Challenges and Troubleshooting

- Adhesive Failure: If Command Strips fail to adhere, check that the surface is properly cleaned and dry. Ensure you're using the right type of strip for the weight of the item.

- Residue: Though Command Strips are designed to leave no residue, older or misapplied strips might leave some adhesive behind. Clean any residue with rubbing alcohol.

- Temperature Extremes: Avoid applying Command Strips in areas exposed to extreme heat or cold, as temperature fluctuations can weaken the adhesive.

Conclusion: Maximizing Command Strip Performance on Metal

Command Strips can be highly effective on metal surfaces when used correctly. By following proper preparation and application techniques, you can ensure a strong bond and reliable performance. Whether you're organizing your office, enhancing your kitchen, or decorating your home, Command Strips provide a versatile and damage-free solution for hanging items on metal surfaces. Embrace the convenience and simplicity of Command Strips and explore the many possibilities they offer for metal surfaces.