How Often Should a Meat Slicer Be Cleaned and Sanitized When in Constant Use?

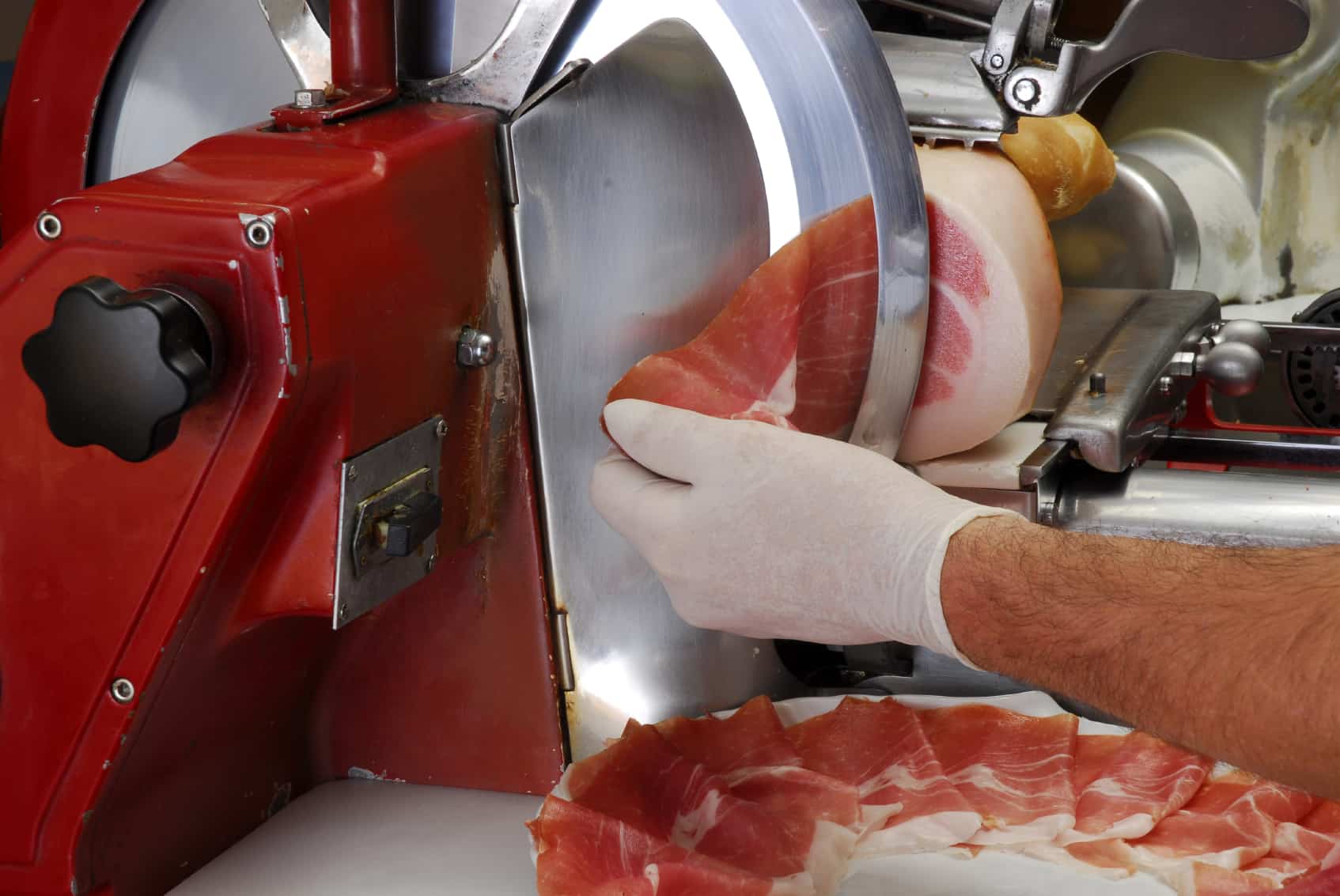

Maintaining proper hygiene in commercial food establishments is crucial for ensuring food safety and preventing contamination. One essential piece of equipment that requires regular cleaning and sanitization is a meat slicer. In this article, we will explore the optimal frequency for cleaning and sanitizing a meat slicer when it is in constant use. By adhering to the recommended guidelines, foodservice operators can minimize the risk of bacterial growth and maintain a safe environment for their customers.

I. Understanding the Importance of Cleaning and Sanitizing a Meat Slicer:

1. Ensuring Food Safety:

A meat slicer is commonly used to slice various types of meats, including cooked and raw. During the slicing process, residue, fats, and other food particles can accumulate on the slicer's surfaces, providing a breeding ground for bacteria.

Proper cleaning and sanitization eliminate these contaminants, reducing the risk of cross-contamination and foodborne illnesses.

2. Complying with Health Regulations:

Health departments and regulatory bodies set specific guidelines regarding food handling and equipment sanitation.

Compliance with these regulations is crucial for foodservice establishments to maintain their licenses and avoid penalties or closures.

Regular cleaning and sanitization of meat slicers are necessary to meet these standards.

at minimum how often must a meat slicer be cleaned and sanitized when in constant use

II. Factors Affecting the Cleaning Frequency:

1. Frequency of Use:

The frequency at which a meat slicer is used plays a significant role in determining the cleaning schedule. The more the slicer is in use, the more frequently it should be cleaned and sanitized.

Constant use implies a higher risk of food residue buildup and bacterial growth, necessitating more frequent cleaning.

2. Types of Foods Sliced:

Different foods have varying levels of moisture, oils, and textures, which can impact the cleanliness of the slicer.

Slicing fatty meats, cheeses, or sticky foods can leave more residue on the machine, requiring more frequent cleaning.

Consider the type of foods being processed to determine the appropriate cleaning frequency.

3. Staff Training and Practices:

Proper training and adherence to cleaning protocols by the staff are essential for maintaining a clean meat slicer.

Regular training sessions should be conducted to ensure that employees understand the importance of cleaning and sanitization and follow the correct procedures.

This helps minimize the risk of neglecting hygiene practices.

III. Recommended Cleaning and Sanitization Schedule:

1. Daily Cleaning:

Regardless of the frequency of use, a meat slicer should be cleaned thoroughly at the end of each day.

This daily cleaning routine involves disassembling the slicer, removing food particles, and washing all the components with hot, soapy water.

Pay close attention to hard-to-reach areas and ensure all surfaces are thoroughly cleaned.

2. Sanitization:

Sanitization is an essential step in ensuring the elimination of bacteria. After the daily cleaning, sanitize the slicer by using a food-grade sanitizer approved by the regulatory authorities.

Follow the manufacturer's instructions for dilution ratios and contact time to achieve effective sanitization.

3. Additional Cleaning During the Day:

In constant use scenarios, it may be necessary to clean the meat slicer more than once a day. Regularly inspect the slicer for any visible residue buildup or contamination.

If significant residue is present, it is advisable to clean and sanitize the slicer between different types of food or after every few hours of continuous use.

at minimum how often must a meat slicer be cleaned and sanitized when in constant use

IV. Best Practices for Cleaning and Sanitizing:

1. Proper Disassembly and Cleaning Technique:

When cleaning a meat slicer, ensure it is unplugged and disassembled according to the manufacturer's instructions.

Clean each part individually, paying attention to the blade, blade guard, carriage, and all other removable components.

Use brushes and scrubbers to remove any stubborn residue, and rinse thoroughly with clean water.

2. Drying and Reassembly:

After cleaning, allow all parts to air dry completely before reassembling the meat slicer. Moisture can promote bacterial growth, so ensure all surfaces are dry before putting the machine back together.

Follow the manufacturer's instructions for reassembly to maintain the slicer's functionality.

3. Record Keeping:

Maintain a cleaning log or checklist to record each cleaning and sanitization session. This documentation helps demonstrate compliance with regulations and acts as a reference for the staff.

Regularly review the records to identify any patterns or areas that may require additional attention.

at minimum how often must a meat slicer be cleaned and sanitized when in constant use

V.Conclusion:

Proper cleaning and sanitization of a meat slicer are paramount to maintain food safety and comply with health regulations.

In constant use situations, it is recommended to clean the slicer thoroughly at the end of each day and sanitize it using an approved food-grade sanitizer.

Additionally, consider additional cleaning during the day if necessary. By following these guidelines and implementing best practices, foodservice operators can ensure a clean and safe environment for their customers.

Remember, a well-maintained meat slicer is an essential component in delivering high-quality food while minimizing the risk of contamination.